Gaode Equipment Co., Ltd. (short:“Gaodetec”) owns the most advanced imported production equipment and complete production technology. Gaodetec is a national high-tech enterprise specializing in the research, development, production, sales and provide service of construction and engineering equipment.

Get Price or Support

foam concrete wall casting machine

-

Part 1: Introduction to Foam Concrete Industrial housing

New wall systems technology enhances designability, energy efficiency and cost The well-known rationale for precast concrete walls includes shortened construction schedules, thermal performance and life span. ... directly into the wet concrete eliminate the need for extrusion equipment and allow Fabcon to cast door and window openings anywhere ...

-

Basement Wall Insulation - NaturalGasEfficiency.org

Part 1: Introduction to Foam Concrete Industrial housing. PART A. Introduction to Foam Concrete Housing SECTION A .1, General Information. A.1.1 Introduction. ... Steel windows and doorframe cast into wall (South Africa) A.2.5 Doorframes and Doors

-

China Foamed concrete casting insulation system - China

Pre-cast concrete slabs are made with rigid foam on the inside. Wood basements are ready to insulate stud walls. There are several foam block systems that involve some sort of stacking foam and then filling the cores with concrete and troweling on a surface coating of concrete or mortar.

-

Cellular lightweight concrete machine for cast-in-situ

China Foamed concrete casting insulation system, Find details about China Foam Concrete Casting Insulation, Lightweight Concrete Wall Casting from Foamed concrete casting insulation system - Hunan Trinity Construction Technology Co., Ltd.

-

RBM

Foam concrete wall is completely contained these characteristics, such as good strength, lightweight weight, thermal insulation and water proof ,etc. In addition, the good integrity and easy operation mean low labor intensity and low construction cost.

-

LIGHT WEIGHT FOAM CONCRETE – POWER PROOF

The use of foam concrete can be seen from these examples: In Light weighted insulating brick, block , roof tiles ,etc. In Building panels and partition walls of various dimensions either pre-cast or cast in-situ.

-

Air-Crete Domes - FAB Online LLC

light weight foam concrete Light weight concrete is a mixture of cement, water and special foam, which produces a strong a lightweight building material combining good mechanical strength with low thermal conductivity.

-

Form Liners for Cast-in-Place Concrete - The Concrete …

Air-Crete Domes; About; Contact; ... Curious to see if this will hold up over time. I have used several cement mixing machines before and this is a new design to me. Connected the drill also so the GD is ready for business! ... In-situ casting of structural (load-bearing) walls and roofs of low rise individual or group housing schemes. (b ...

-

RBM - Foam Concrete Machine

Form Liners for Cast-in-Place Concrete ... we are primarily reviewing form liners used inside the forms for cast-in-place concrete walls-although the liners and techniques are really no different for precast concrete. ... a CNC milling machine creates various thicknesses of lines onto sheets of form liner materials. The resulting images in the ...

-

Concrete Casting Forming System Foam Rails and Tapes …

RBM 3 in 1 Foam Concrete Machine Model :RBM-2000 (Patent Granted MY-133290-A) is a multi-function machine that integrated with SMART & INNOVATIVE technologies for different type of application & comply with building requirement in green, systematic and energy efficient way.

-

Disadvantages of Concrete Basement Walls | Composite …

SureCrete’s XS concrete casting forming system foam rails and tapes are easy to use and help in eliminating ripping material, screwing, nailing, and in most cases, caulking to create the side rails in forming precast projects.It consists of 3 elements: Polystyrene foam rails, Clear facing tape and PSA tape for casting concrete countertops and precast panels.

-

Weiler GmbH - Concrete Slipformer and Extruder Machines

Disadvantages of Concrete Basement Walls Concrete can crack and leak anywhere While historically preferable to other traditional building materials, concrete has many important drawbacks, such as overall mass, installation time and poor insulating properties.

-

How to Build With Faswall® Concrete Form Material

Founded in 1954 with over 200 plants and 500 precast extruder and slipformer machines worldwide, Weiler GmbH manufactures machines and plants to produce precast, prestressed hollow core concrete slabs, concrete planks, wall panels, t beams, and architectural precast products.

-

LithoPore 600–1600 | Luca Industries International GmbH

The concrete form material blocks are cast from a mixture of K-X Aggregate (mineralized wood chips) and Portland cement. The wall forms are designed as stay-in-place units, which become part of a load-bearing wall only after being filled with reinforced concrete.

-

Removable Forms (Cast-In-Place) - cement.org

With a foamed concrete machine by Luca Industries International several houses per day can easily be manufactured. After the wall molds are positioned the foamed concrete can be cast into them. The final step is the removal of the molds.

-

Precast concrete Manufacturers & Suppliers, China precast

Cast-in-place (CIP) concrete walls are made with ready-mix concrete placed into removable forms erected on site. Historically, this has been one of the most common forms of building basement walls. The same techniques used below grade can be repeated with above-grade walls to form the first floor ...

-

cellular concrete | cellular concrete technologies

precast concrete manufacturers & suppliers found with 1,368 products . ... Concrete Wall Panel Machine , Concrete Hollow Core Roofing Slab Machine , Precast Concrete Lintel/Beam Machine ... Precast Nano Interlock Foam Concrete Block Molds.

-

What is the foam concrete ?? And where can I use it

Throop Cellular Concrete is ready to tackle your engineering and design challenges with regards to all types of cellular concrete installations

-

Aerated Concrete, Lightweight Concrete, Cellular Concrete

Foam concrete is typically pumped on site to make forms such as retaining walls and foundations. Foam concrete is a cement material manufactured by mixing a cement paste, also called slurry, or mortar with a manufactured foam material. ... Brick Making Machine Sale. ... Foam concrete made with cement and foam only is typically used in roofs and ...

-

A Century of Tilt-up| Concrete Construction Magazine

In most cases, on-site stack-casting of panels is employed, using ready mix trucks which are charged with sand, cement and water before the foam is added. The trucks discharge the lightweight concrete directly into the molds.

-

CLC Equipments & Technologies | THT International

Wall panels were cast on a framed tilt-table, face up so precast architectural elements could be attached. The entire assembly was tilted up with jack screws. Once vertical, the concrete panel was braced and the tilt-table was stripped, lowered, and prepared for the next panel.

-

FORMABLOK Segmental Concrete Block Molds, Vancouver …

CLC Wall Panel ; Heat insulation panel ... We are one of the leading company in the lightweight foam concrete field. We have developed and exported our machines to many countries in America, Europe, Africa and Asia such as: foam concrete block cutting machine, cellular concrete mixer, lightweight concrete pump, foam generator, clc plant ...

-

Cellular lightweight concrete machine for cast-in-situ

Anyone can FORMABLOK...home gardeners, landscapers, contractors. Sustainable building product, reduce carbon footprint AND save money! Build retaining walls, steps, firepits...more! EASY DIY!

-

Precast concrete | YourHome

Foam concrete wall is completely contained these characteristics, such as good strength, lightweight weight, thermal insulation and water proof ,etc. In addition, the good integrity and easy operation mean low labor intensity and low construction cost.

-

hot sell foam concrete wall making machine - gildan.in

Precast concrete offers durable, flexible solutions for floors, walls and even roofs in every type of domestic construction from individual cottages to multi-storey apartments. Concrete’s high initial embodied energy can be offset by its extended life cycle (up to …

-

lightweight wall panel machine,foam concrete wall panel

concrete mold making & casting with smooth on. ... hot sell lightweight foam concrete wall panel machine, hot sell lightweight foam concrete wall panel machine,us $ 15,000 18,000 / set, new, prestressed concrete wall panel, concrete.source from …

-

Precast concrete - Wikipedia

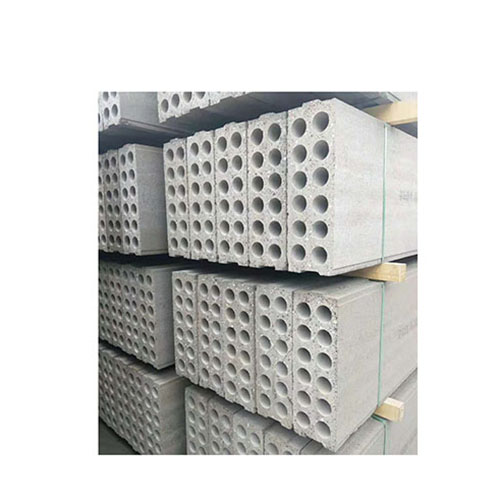

lightweight wall panel machine,foam concrete wall panel machine,Precast concrete hollow core slab machine,prestressed hollow core slab machine,hollow core slab extruder machine,prestressed concrete hollow core slab machine, weiler technology hollow core plank machine,concrete fence panel machine

-

Used concrete equipment - Precast Concrete Machinery

Used precast concrete machinery: block making ... palletizing machines, machines for hollowcore slab production and more. Used precast concrete machinery: block making machines, multilayer paver machines, palletizing machines, machines for hollowcore slab production and more ... sandwich walls, double walls as well as concrete shuttering ...

-

Foamed Lightweight Concrete | Natural Building Blog

Foamed Lightweight Concrete — 77 Comments Barry Murray on April 16, ... Our company (www.lightconcete.net) has supplied machinery and equipment for foam concrete to 12 countries around the world, including USA. ... The foam cement hangs well on a wall when you throw it, but troweling it causes sagging. ...