Gaode Equipment Co., Ltd. (short:“Gaodetec”) owns the most advanced imported production equipment and complete production technology. Gaodetec is a national high-tech enterprise specializing in the research, development, production, sales and provide service of construction and engineering equipment.

Get Price or Support

foam cement production for concrete wall boards

-

Installing Foam Board Insulation on an Exterior Wall

It is recommended that you install foam board insulation for exterior walls of concrete, foundations, concrete slabs, basement walls and crawl spaces. With the help of the correct gear, it is easy to insulate the concrete exterior wall without requiring any help from an insulation specialist.

-

EPS Cement Sandwich Panel manufacturer - quality Precast

Quality EPS Cement Sandwich Panel, Precast Concrete Wall Panels & Composite Panel Board suppliers & exporter - all products made in China.

-

Cement EPS Dry Wall Panel Production Line Machine

Main materials to produce the light weight wall panel and the foam cement wall panel are: Cement,fly ash,water,foam polystyrene particles,additives. Application of the foam eps light weight wall panel: As Internal&external wall partition,roof,floor for residential building,villa,school,shopping center,commercial building,etc.

-

Exterior Wall Insulation for New and Existing Concrete Block

Exterior Wall Insulation for New and Existing Concrete Block One of the major sources of air and heating loss occurs through the walls. By reducing your air infiltration with our foam process, you can keep the cool air inside and that hot and humid Central Florida air outside!

-

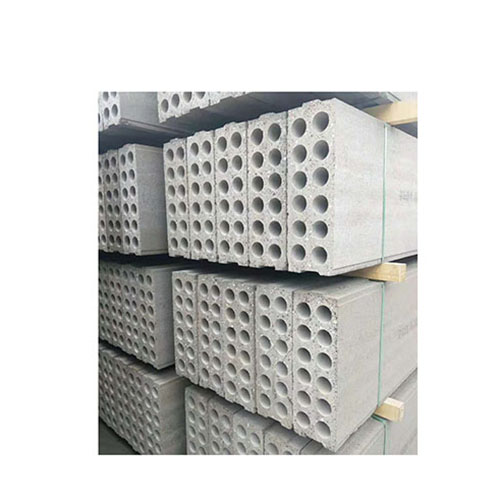

Professional anti quake light weight sandwich wall panel

Quality Sandwich Wall Panel manufacturers & exporter - buy Professional anti quake light weight sandwich wall panel OF EPS foam + cement from China manufacturer.

-

Building Walls with Low Velocity Sprayed Concrete

Above: Placing panels of expanded polystyrene foam with reinforcing mesh on each side is easy and fast. Low velocity concrete is sprayed on both sides of the panel to construct walls that can handle both seismic and high wind forces.

-

OT: attaching 2" foam insulation board to exterior block wall.

Sep 10, 2014· Drilling into concrete and block walls is a PITA in my opinion. Tapcons especially in block walls only hold about 75% percent of the time (for my amateur hands). ... Also, the foam board is already against the wall and hole is 80 percent filled with wash gravel at this point. used this on the seams of the foam board.

-

Genfil Herbal Resin Based Foam agent - Foam concrete

GENFIL® (foam agent) improved high-yield herbal resin based foam agent in the construction industry for the manufacture of concrete and lightweight construction Diluted GENFIL® (foam agent) with water that applying in foam machine for getting foam. The foam mixing with cement and gypsum mortar that be obtained insulated lightweight structural elements.

-

Foam Agent | Turkey | Artra Foam Concrete Technologies

The AFT 500 series of foam reagents provide cement/concrete with very low water uptake. Cementitious foams at densities as low as one tenth (1/10) ... The typical rate of foam production is from 3 to 20 cu. ft. per minute (depending on the model used). These foam genera- ... wall panels, construction bricks and blocks, their room

-

How To Attach Rigid Foam Insulation To Concrete | How …

Cement board, shakes or shingles may also be applied by ... Residential Installation Instructions . Above-Grade Exterior Walls 3: Concrete / Block Wall –Separate WRB Stucco Maximum 1-1/2” Insulation ... Install AP Foil- Faced boards horizontally or vertically over concrete or block wall. Use maximum board lengths to minimize the number of ...

-

How to Insulate a Basement | This Old House

panels used in floors, walls, and roofs for residential and light commercial buildings. The panels are typically made by sandwiching a core of rigid foam plastic insulation between two structural skins.

-

Anti-Seismic Sound Concrete Foam Board EPS Cement …

We supply I. Foam agent and additives as liquid and powder II. All Machinery and Equipment for producing foam concrete III. Plant Projecting and consulting services for block production.

-

Attaching rigid foam to concrete | Fine Homebuilding

Saif Mostaghim: I have a kitchen above ground with one wall to outside, I want to insulate it with rigid foam. The drywall was attached to 3/4 inch wood slats. I want to add one more layer of wood slat over the existing one to be able to put 1 to 1.5 inch rigid foams behind drywall.

-

Foam Cement Machine MAS | MAS Paints

How to Insulate a Basement. Shopping List. 1. Plant mister, used to spray water onto the tie-rod holes. 2. Hydraulic cement, for plugging tie-rod holes in concrete wall. 3. 2-inch-thick rigid polystyrene, used to insulate wall. 4. Foam board adhesive, for adhering foam board to concrete wall.

-

How to Make Concrete Foam | Hunker

EPS Cement Sandwich Panels, Cement Board, EPS Sandwich Panel manufacturer / supplier in China, offering Anti-Seismic Sound Concrete Foam Board EPS Cement Sabdwich Panel for Building, Fpb Panel Sandwich Interior Lightweight EPS Bathroom Use Waterproof Cement Sandwich Panel, Construction Materials Composite Sandwich Wall Panel for High Building and so on.

-

How to Install Rigid Foam Insulation on Concrete

Use a gun adhesive foam, like EnerBond SF... set a 4x8 sheet of foam board on the ground, glue the top, then set a 4x8 sheet of OSB on top of it. Drill through and use a tapcon through the OSB/foam to secure it to the concrete (hint: the same foam adhesive will work on the concrete).

-

foam cement | eBay

Used for the production of low density foamed mortar and concrete, as flat roof insulation screeds, insulated floor screeds, as a backfill concrete, fabrication of light weight beams, blocks and panels, fire barrier, sound insulation of walls and ceilings, or encasement concrete.

-

GLUING rigid foam board onto cement, then gluing drywall

The cement-based slurry that creates foam concrete is made up of a foaming agent and typical mortar. Concrete foam was originally used as insulation in the 1920s. The material was brought into home construction projects in the '80s where it was used as an inexpensive patch alternative for walkways and walls.

-

Cellular Lightweight Concrete (CLC) – Edama Germany

CFI Concrete Faced Insulated Wall Panels ... Concrete Faced Insulated (CFI®) Wall Panels are a pre-finished, “One-Step” exterior perimeter foundation or low-rise wall insulation panel consisting of STYROFOAM™ brand foam insulation with a factory applied 5/16"(8mm)(nominal) thick

-

Structural Behavior of Precast Lightweight Foam Concrete

For Concrete basement walls where you plan to install furring strips for drywall, install the furring strips before gluing the insulation panels to the wall. When you have the furring strips attached, measure and cut the insulation panels to fit between the furring strips.

-

Cement board stucco exterior wall system details and

Find great deals on eBay for foam cement. Shop with confidence.

-

Foam concrete - Wikipedia

I want to just glue foil-faced-foam right onto the cement walls of the basement, then glue drywall onto the foam. "Great Stuff" [aka Dow] makes this spray-foam you can glue rigid foam board …

-

Insulate Between Walls With Rigid Foam - The Spruce

Edama foam concrete is a mixture of cement, fine sand, water and a special foam, which produces a strong, lightweight concrete containing millions of evenly distributed, consistently sized air bubbles, or cells. The density of Foam Concrete is determined by the amount of foam added to the basic cement, sand and water mix.

-

Basement walls - gluing foam/drywall - Forum - Bob Vila

The ratio used for cement: aggregate: sand is 1 : 2 : 4 with foam cement ratio of 0.65 and water cement ratio of 0.5. The materials used in foamed concrete are foam, cement, fine sand and water. The foam was produced by mixing one part of foam agent (in liquid form) to forty parts of water in the foam …

-

Cement Boards 101 - Global Cement

INTRO. An air barrier Cement board stucco exterior wall system minimizes the risk of condensation within the building envelope. It does this by eliminating mass transfer of warm moisture air into the wall assembly to a cold surface where it can condense.

-

Foam Concrete - Revolvy

Foam concrete, also known as aircrete, foamed concrete, foamcrete, cellular lightweight concrete or reduced density concrete, is defined as a cement based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar.

-

The correct method of using rigid foam is to run continuous 4' x 8' sheets across the concrete, making it the de facto wall. After that, thin furring strips are installed on top of the foam to give the drywall screws something to bite into.

-

Basement walls - gluing foam/drywall Tags: Basement & Foundation Has anyone every heard of finishing off basement perimeter walls by gluing styrofoam insulation to the concrete and then gluing ...

-

Cement Boards 101. 19 December 2013 Picture 4: Fibre cement board (FCB). ... There are three processing methods employed for the production of fibre cement board, namely the Hatscheck process, the Extrusion process and the Perlite process. ... followed by the application of a concrete weight for 24 hours to promote bonding, which also acts to ...

-

Oct 07, 1970· Save. Foam concrete, also known as foamed concrete, foamcrete, cellular lightweight concrete or reduced density concrete, is defined as a cement based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar. [1] As mostly no coarse aggregate is used for production of foam concrete the correct term would be called mortar instead of concrete.