Gaode Equipment Co., Ltd. (short:“Gaodetec”) owns the most advanced imported production equipment and complete production technology. Gaodetec is a national high-tech enterprise specializing in the research, development, production, sales and provide service of construction and engineering equipment.

Get Price or Support

cellular lightweight concrete insulation wall panel machine

-

Cellular Lightweight Concrete (CLC) - alviko.su

CLC (foam concrete) blocks are used for building cottages, wall insulation in multistory buildings and internal partitions. Also CLC can be produced and poured for floors and roofs on-site. In roofs it can be used because of very good insulating and lightweight.

-

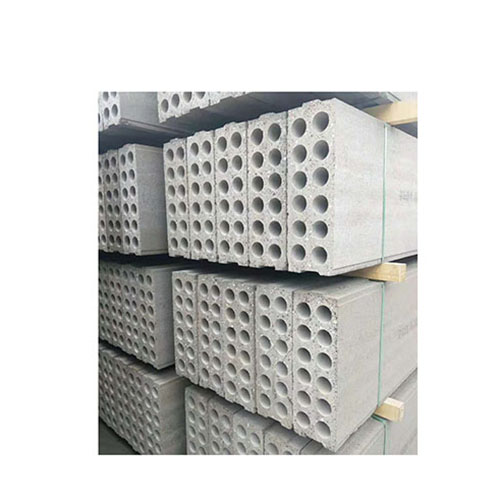

Lightweight concrete heat insulation panel for sale

Heat insulation panels made from lightweight concrete developed by THT International are highly resistant to fire and heat. The product is made of cement, gypsum, lightweight concrete, additives and synthetic fiber to enhance strength, reduce weight and increase heat insulation properties.

-

CellularFibroConcrete.com - Application in roof construction

Cellular Fibro Concrete, which is lightweight, possesses high frost resistance and good thermo- and sound insulating properties, is a very suitable material for construction of flat (level) roofs. For construction of sloping roofs most effective is the use of pre-cast slabs or panels from CFC.

-

Nanotechnology for lightweight cellular concrete | Dubai

ECOCON concrete (gasbeton) is a type of non-autoclaved aerated lightweight cellular concretes that is manufactured in the form of dry mix (powder) and can be turned into lightweight cellular concrete by simple mixing with water.

-

Welcome to LITECRETE

Welcome to LITECRETE. Litecrete lightweight precast concrete is manufactured using local pumice aggregate. The pumice provides both in-built insulation and a 40% weight reduction compared to standard precast concrete.

-

Coretech Africa | Cellular Concrete

CLC is an air-cured lightweight concrete that can be produced at project site, utilizing equipment and molds normally in use for conventional concrete. Utilizing, the most traditional mixers and very successful truck mixers to produce cellular concrete, by installing and integrating a foam generator, into the existing concrete or prefab plants ...

-

Insulated Lightweight Foamed Concrete

Brief History. Cellular Concrete was first developed in Stockholm, Sweden in the early 1900’s. The original material was known as “gas concrete” to be used in producing heat-insulated building materials.

-

foam generators for foam concrete

Designing, Developing and Testing of Cellular Lightweight Concrete Brick (CLC) Wall built in Rat-Trap bond A. K. Marunmale1, A.C.Attar2 ... insulation, partition wall, non load bearing external wall 5 Compressiv e strength kg/cm2 20-80 30-150 25-40 6 Block size LxBxH mm

-

Provoton Foam Concrete, lightweight cellular concrete

Foamed light weight concrete in the form of bricks, blocks or poured in-situ is used for thermal insulation over flat roofs or for cold storage walls or as non-load bearing walls in RCC/Steel framed buildings or for load bearing walls for low-rise buildings.

-

Aerated Concrete, Lightweight Concrete, Cellular Concrete

Provoton Foam Concrete, foam generators, foam concrete production equipment, cellular concrete, lightweight fill, low density, insulating concrete, MSE wall backfill ...

-

Autoclaved aerated concrete - Wikipedia

In tests undertaken in Australia, a LITEBUILT® aerated lightweight concrete wall panel, 150 mm (6") in thickness was exposed to temperatures in the vicinity of 1200°C (2192°F), with the unexposed surface only increasing by 46°C (115°F) after 5 hours.

-

Cellular Lightweight Concrete - Manufacturers, Suppliers

LIGHTWEIGHT CEMENT/CONCRETE Allied Foam Tech Corp. Description: Allied AFT foam systems provide ... available in the construc-tion industry. The AFT series of foam agents, using compressed air and AFT foam generating equipment, gener-ate very fine and stable foams. They provide cement, concrete and gypsum mixes with reduced ... wall panels ...

-

STRUCTURE magazine | Cellular Concrete

Cellular Lightweight Concrete (CLC) bricks are environment friendly and manufactured from common natural raw material. The energy consumed in the production process is only a fraction compared to the production of other materials and emits no pollutants and creates no toxic products or by products.

-

Part 1: Introduction to Foam Concrete Industrial housing

Cellular concrete is a carefully crafted mixture of cement, water and pre-formed foam. This material is mixed to a specified density and pumped into any void. The fundamentals are simple, but the applications and the ability to mix properly and at high production rates can be challenging.

-

What is Lightweight Concrete? -Types, Uses and Advantages

Once the mould for the walls is set up and ready for casting, it is filled with lightweight concrete. The most suitable material is Foam Concrete (FC), also known as Cellular Lightweight Concrete (CLC).

-

PPT - Cellular Lightweight Concrete (CLC) PowerPoint

Aerated concrete is a lightweight, cellular material consisting of cement and/or lime and sand or other silicious material. ... Construction of partition walls and panel walls in frame structures. Fixing bricks to receive nails from joinery, principally in domestic or domestic type construction. General insulation of walls. Surface rendered for ...

-

Lightweight Cellular Concrete (LCC) | CNCA - Cement

Cellular Lightweight Concrete (CLC) is conventional concrete, where natural aggregate (gravel) is exchanged for the best insulation medium available, namely air, embedded in organic and bio-degradable foam that offers no chemical reaction but solely serves as wrapping material for the air.

-

The New Hybrid Thin-Shell Precast Wall System - National

The Lightweight Cellular Concrete Solution. Lightweight Cellular Concrete, also referred to as foam concrete is produced by the addition of an air-entraining agent or a preformed foam to a slurry of portland cement, fly ash, water, and occasionally, aggregates.

-

Description of foam concrete and cellular lightweight

Lightweight Construction Methods (LCM) (also known as foam concrete (FC)/cellular lightweight concrete (CLWC)) were developed more than 60 years ago and since then have been used internationally for different construction applications.

-

Foam concrete - Wikipedia

Cellular Concrete Cellular Concrete is a cementitious paste of neat cement or cement and fine sand with a multitude of micro/macroscopic discrete air cells uniformly distributed throughout the mixture to create a lightweight

-

Fireproof panel-Trinity China- Foam Concrete Machine

The New Hybrid Thin-Shell Precast Wall System. ... is simplified because one can use lighter weight equipment to lift the panels or opt to use fewer but larger panels. Panels as big as 16 feet by 40 feet have been used. ... a new type of studcast precast made with lightweight cellular concrete for improved thermal properties and fire resistance.

-

ECOFAST Construction – ECOnomical, ECOlogical, & FAST

Foam concrete use for producing construction blocks, thermal and acoustic insulation of roofs, floors, warming of pipes, production of collapsible blocks and panels of partitions in buildings, as well as floors and basements foam concrete of higher density.

-

THE PRODUCTION - Universiti Sains Malaysia

Foam concrete, also known as aircrete, foamed concrete, foamcrete, cellular lightweight concrete or reduced density concrete, is defined as a cement based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar.

-

Load Reducing Backfill Cellular Concrete Services - …

Foam Concrete Fire Proof door fill-in and wall panel . China’s new policy requires fire door fill-in refractoriness to be above 1100℃ as well as strength and insulation features.

-

Formulas for Lightweight Concrete - Green Home Building

ECOFAST Construction is a pioneer in advanced Envelope and Core & Shell Solutions for Buildings & Residential Compounds with light gauge steel framing and cellular lightweight concrete, providing a competitive alternative to more standard construction solutions all over the GCC and particularly in its base in the UAE.

-

Cellular cement can have lower densities (400 - 700 kg/m3) but their strength is lower than foamed (cellular) concrete and can only be used for insulation (e.g. roof screeds) or void filling applications.

-

Load Reducing Backfill Foam concrete offers significant advantages in projects that require lightweight fill. Densities can be varied from 20 to 60 PCF and compressive strengths from 50 …

-

Concrete Faced Insulated Wall Panels ... specification for Rigid Cellular Polystyrene Thermal insulation – AsTM C518 - standard Test Method for steady-state Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus – AsTM D1621 - standard Test

-

Formulas for Lightweight Concrete. ... Another possibility would be the easiest---go to www.google.com and type in cellular concrete and you will find the manufacturers , information, etc, etc. ... I would like a specific lightweight concrete formula for house walls that has some structural qualities reasonable insulation qualities and can ...