Gaode Equipment Co., Ltd. (short:“Gaodetec”) owns the most advanced imported production equipment and complete production technology. Gaodetec is a national high-tech enterprise specializing in the research, development, production, sales and provide service of construction and engineering equipment.

Get Price or Support

aac light weight construction materials,fly ash,aluminium powder

-

Autoclaved aerated concrete(AAC) Blocks Bangalore

Autoclaved aerated concrete(AAC) Blocks. Formed as a result of reaction of Aluminum on a proportionate blend of lime, cement & Fly ash, the hydrogen gas that escapes creates millions of tiny air cells giving it a strong Cellular structure which is further strengthened by high pressure steam curing in Autoclaves known as AUTOCLAVED AERATED CONCRETE BLOCK.

-

AAC Fly Ash Bricks, Bricks, Concrete & Building Material

These bricks are processed with the mixture of fly ash, cement, lime powder, gypsum, aluminium powder etc. The offered bricks are widely used for constructing, …

-

AAC PLANT - AAC Block Plant (Autoclaved Aerated

Keywords – AAC, bricks, light-weight, building, material ... AAC is produced out of a mix of quartz sand or pulverized fly ash, lime, cement, gypsum/anhydrite, ... is aluminum powder; this material reacts with calcium hydroxide which is the product of reaction between cement and

-

Autoclaved Aerated Concrete (AAC) Market Size, Share

AAC Block are made of fly ash as main raw material, cement, lime & aluminum powder. Gypsum acts as a long term strength gainer. The plant is able to make extreme light weight and large variety of sizes blocks and has excellent thermal insulation nature.

-

Buildmate Products: AAC Plant Supplier Hyderabad, India

Autoclaved cellular concrete comprises basic materials such as gypsum, fly ash, aluminum powder paste, cement, sand, lime, and water. The chemical reaction among alkaline elements and aluminum paste in the cement offers AAC with distinct lightness, insulation properties and porous structure which are entirely different from other lightweight ...

-

AAC Block Production Line ~ LONTTO MACHINE

(autoclaving).the raw materials of the AAC block is fly ash, cement, aluminum powder, gypsum, lime. And water.AAC blocks offer superior performance and reduced project cost due to bigger size and light weight …

-

Autoclaved Aerated Concrete: CCPs Growth in Asia Pacific

It is a lightweight material produced by mixing silica rich material (sand or fly ash), cement, lime, gypsum, aluminium powder and water. AAC blocks manufacturing is a growing industry in India which is going to bring drastic changes to the construction industry.

-

AAC Block & Fly Ash Bricks Suppliers Chhattisgarh - Ecorex

Autoclaved Aerated Concrete (AAC): A Sustainable Building Material Introduction Autoclaved aerated concrete (AAC) is a derivative of fly ash that is combined with cement, lime and water and an aerat-ing agent. AAC is produced as blocks and panels. ... proved eco-friendly building material that comes from industri - al waste and is made from non ...

-

Aac Lightweight Blocks - Manufacturers, Suppliers

AAC block production line is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder ect., through batching, mixing, casting ,cuttimg and autoclaving. AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great scousitc insulation and high fire resistance.

-

Aac Block - Manufacturers, Suppliers & Exporters in India

The construction material consists of fly ash and gypsum, both biproducts of burning coal to make energy, and much less costly than their alternatives, sand and anhydrite. The material also consists of lime, cement, and aluminum powder.

-

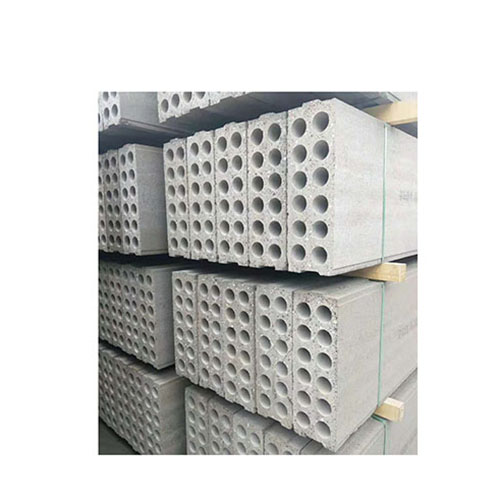

China Concrete Lightweight AAC Block Autoclaved Aerated

AAC block is a light weight precast building material that offers a unique combination of strength, low weight, cost effectiveness, speed and durability. It is also an environment friendly product, as it is manufactured using 60-65% of fly ash (by weight), an unavoidable …

-

Concrete Solution for AAC Block Plant - camelway.com

Airolite AAC Blocks is a lightweight material produced by mixing silica rich material (sand or fly ash/pond ash), cement, lime, gypsum, aluminum powder/paste and water. Aluminium acts as a catalyst. It generates hydrogen gas upon reacting with cement and lime during AAC …

-

Anjali Infracrete, India’s pioneering provider of

Airolite AAC Blocks is a lightweight material produced by mixing silica rich material (sand or fly ash/pond ash), cement, lime, gypsum, aluminum powder/paste and water. Aluminium acts as a catalyst. It generates hydrogen gas upon reacting with cement and lime during AAC …

-

AAC Blocks Supply PAN India – Brickwell

AAC is a new type building material where the raw materials are siliceous materials (fly-ash, sand, slag), calcareous materials (lime, cement and gypsum) and Aluminium powder. AAC product has been widely used in industrial and civil construction.

-

AAC blocks supplier in kolkata..Magic Zone International

Most of the AAC companies in the world use fly ash to manufacture AAC blocks. Fly ash is mixed with water to form fly ash slurry. Slurry thus formed is mixed with other ingredients like lime powder, cement, gypsum and aluminium powder in quantities compliance with the recipe.

-

AAC Block Production Line | QUNFENG

Aluminum powder along with Fly ash, cement, lime, gypsum, surfactants in slurry form is mixed in high speed –Automatic batch mixer resulting in AAC slurry;

-

Autoclaved Aerated Concrete - cement.org

Supply of Aerated Autoclaved Concrete Blocks ( AAC) Brickwell frim is occupied with the business of imaginative building materials and pre-assembled development innovations and is one of the biggest producer of Autoclaved Aerated Concrete Blocks.

-

Kansalindia – AAC BLOCKS

AAC Blocks. AAC block is produced out of a porous cake moulded from a mix of quartz sand or Pulverized Fly Ash (PFA), lime, cement, gypsum, water and aluminium powder.

-

Properties of the autoclaved aerated concrete produced

ACC is a lightweight building material which can be manufactured using water, cement, aluminum, and up to 70% fly ash by weight. Manufactured in blocks or panels, ACC

-

Fly ash brick - Wikipedia

AAC blocks are made using fly ash (lime slag or sand) as the main raw material, cement and lime as the cementing materials, and aluminum powder as the foaming agent. The main forming procedures are as follows: material crushing, measuring, mixing, pouring, curing, cutting and steaming.

-

AAC Light Weight Fly Ash Sand Brick Cutting Machine from

AAC(Autoclaved aerated concrete ) is a light weight concrete material that was developed in many years ago, the main constituents used in making of this type of concrete is cement grade53 , gypsum, class C lime (hydrated lime), aluminum powder(.05-.25% by wt of cement) , fine

-

AAC Brick Making Machine, AAC Block Production Plant

Autoclaved aerated concrete offers both material and performance aspects from a sustainability perspective. On the material side, it can contain recycled materials like fly ash and rebar, which may help contribute to credits in LEED® or other green rating systems.

-

replace the clay brick with light weight AAC blocks. The usage of AAC block reduces the cost of construction up-to 25% as ... gypsum, lime and aluminum powder; fly ash being very important for manufacturing process. Raw materials are mixed to a slurry ... Primary raw material for AAC blocks is fly ash. Fly ash is industrial waste generated by ...

-

Autoclaved Aerated Concrete Masonry Units (AAC) are ... lime, water, sand or fly ash, and aluminum. The sand is ground to a powder-like consistency and mixed with the remaining materials to form a slurry. ... per inch of any building material. A 4” AAC wall carries a 4-hour (UL) rating. AAC is non-combustible – it will not

-

AAC, a light-weight green building material, is fire resistant and has good thermal insulation, solid structure and is easy to work with. AAC is manufactured by about 200 plants in 35 countries and is used extensively in residential, commercial and industrial buildings.

-

Coal fly ash is a well-known substitute material, a binder or aggregate for the production of concrete and nowadays a large amount of fly ash has already been utilized in the construction industry as a partial cement replacement or mineral additive in cement production.

-

Fly ash brick (FAB) is a building material, specifically masonry units, containing class C or class F fly ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw cycles.

-

AAC Light Weight Fly Ash Sand Brick Cutting Machine from China, US $ 400,000 - 800,000 / Set, New, Autoclaved Aerated Concrete Block Making Machine, lime, cement, fly ash, gypsum, aluminium powder.Source from Shandong Gaotang Huatong Hydraulic …

-

Shandong Sunite Machinery Co., Ltd. AAC Block Making Machine, AAC Machine Making Machine Line, AAC Brick Machine manufacturer / supplier in China, offering AAC Brick Making Machine, AAC Block Production Plant, Lightweight Block Machine, AAC Machine, AAC Panel Production Line /Alc, Fly Ash Lightweight AAC Block Making Machine Factory and so on.